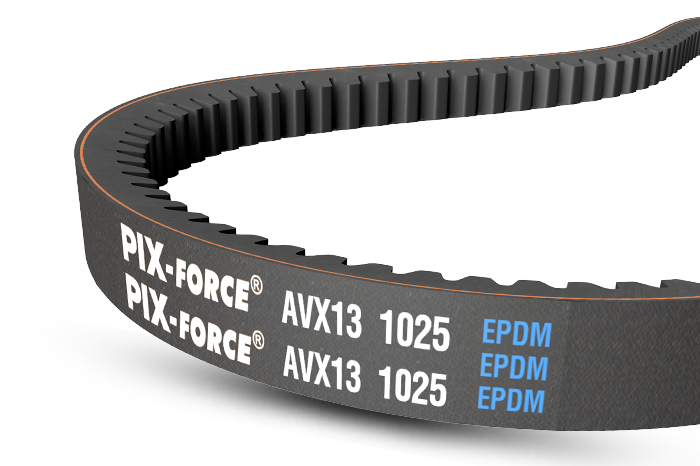

PIX-FORCE® 拖拉机皮带

适用于离合器传动

反向弯曲

高抗拉强度

最小伸长率

防静电

耐油

耐热性

温度范围 -45°C to +120°C

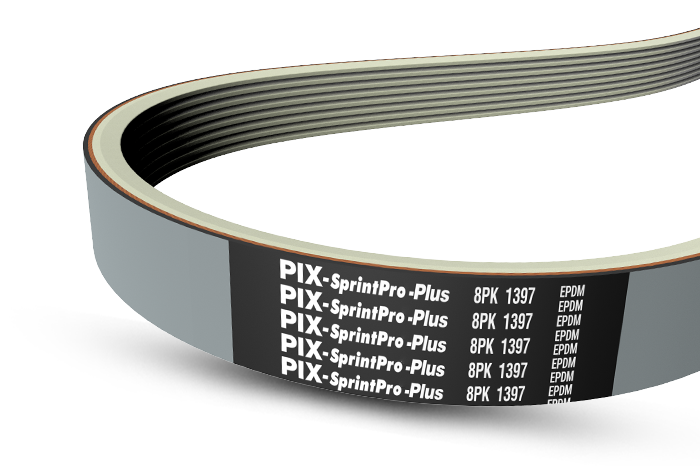

封面

耐磨、橡胶处理的聚酯帆布

多层粘结胶

EPDM粘结胶化合物

线绳

聚酯线绳

压缩矩阵

EPDM结构

Experience the product

Our stunning interactive 3D Belt model allows viewers to get a hands-on experience with products by allowing them to view them from any angle or scale with rich rendering.

Augmented Reality (AR)

3D Viewer

Any Device

Any Browser

常見問題

Tractor Belts are specialized Belts used in tractors to transfer power from the engine to various components, enabling operations like driving, steering, and powering auxiliary machinery.

These Belts transmit power from the engine to components like the transmission, PTO (Power Take-Off), hydraulic systems, and accessories such as fans or pumps.

Common types include drive Belts for the engine, PTO Belts for power transmission, hydraulic Belts, fan Belts, and specialty Belts designed for specific tractor models or components.

They are typically made from durable materials like rubber compounds reinforced with synthetic materials such as polyester, aramid fibers, or metal cords for strength and wear resistance.

Replacement intervals depend on usage, load, and environmental conditions. Regular inspection and adherence to maintenance schedules are crucial for optimal performance.

Signs include visible wear, fraying, cracking, loss of tension, increased noise during operation, reduced efficiency, or reaching the recommended service life specified by the manufacturer.

Replacing Tractor Belts might require specific tools and expertise due to the variety and complexity of tractor systems. Professional assistance or trained technicians may be recommended.

Regular inspection for wear, proper tension adjustment, alignment checks, and following manufacturer-recommended maintenance schedules are crucial for maximizing belt lifespan and efficiency.

Yes, harsh conditions such as dust, moisture, heavy loads, or exposure to chemicals can impact belt performance, requiring frequent inspection and maintenance.

High-quality Belts offer durability, resistance to wear, reliability in heavy-duty operations, and efficiency, contributing to smoother tractor functionality and reduced downtime.